Common Sense Essential for Purchasing Diamond Powder

-2023-03-09 17:15:00 -

Understanding the knowledge of judging the quality of diamond can help you better buy and use diamond products.

This article will describe the common sense of diamond powder from six angles.

1. The impact strength of diamond powder

Impact strength is a scientific and comprehensive quality index, and static pressure strength is the most commonly used method in China to measure the quality of diamonds.

2. Magnetic susceptibility of diamond powder

Due to the use of metal as a catalyst in the synthesis of diamond, different diamond impurities are contained inside, especially the inclusions inside the crystal, which make diamond magnetic. It is convenient and nondestructive to measure the magnetic susceptibility to characterize the properties of diamond such as impurities, toughness, strength, specific gravity, thermal stability, etc., which has important practical value. The less impurity content, the smaller the magnetic susceptibility, the smaller the specific gravity, the lighter the color, the better the transparency, the higher the impact toughness, and the smaller the brittleness

3. Color

The color of diamond crystals is affected by temperature and the chemical environment in which they are located. The diamond crystals grown at low temperatures are darker in color and lighter in color at high temperatures. Various trace elements (impurities) as the crystal grows to determine the color of the diamond. For example, a small amount of boron will make the diamond crystal appear sky blue, and a large amount of boron will make it black (commonly known as black diamond). Nitrogen enters the diamond crystal to produce a yellow diamond, and most artificial diamonds are this kind of diamond. Aluminum prevents nitrogen from entering the growing diamond crystal. Make diamond crystals colorless. (natural diamond color).

4. Granularity

The concentration, uniformity, and tolerance range of diamond particle size are also important indicators for judging the quality of diamond. The particle size can be seen through a microscope, and it cannot be too large or too small. The particle size concentration should be high, and the tolerance range has a great influence on the electroplating diamond tools. In the electroplating tools, if the tolerance requirements are involved, the relevant tolerance requirements cannot be less than the range in this table, otherwise, the error of the diamond itself will already lead to tool failure. The overall requirements are not up to standard.

5. Transparency

When diamond is synthesized at high temperature and high pressure, the crystal nucleus first grows at the junction of graphite and a metal catalyst. If the crystal growth is too fast, the metal will be wrapped in the diamond crystal, forming small black spots of impurities. Because the thermal stability of impurities is not good, they will first expand and crack the diamond from the inside when exposed to heat, thus affecting the strength of the diamond.

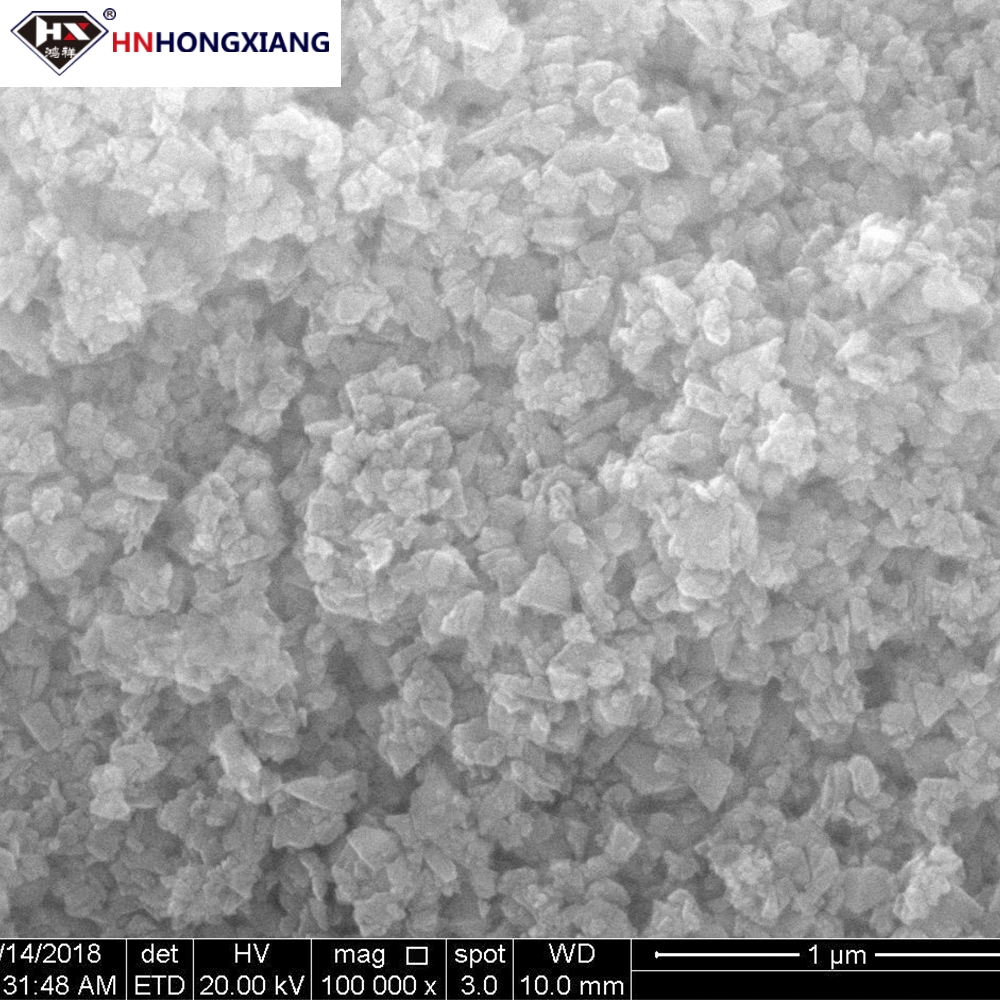

6. Crystal form

The growth rate and shape of diamond crystals are more sensitive to pressure. Higher pressure causes more nucleation, faster growth rate, and easy formation of octahedral crystals. Diamond crystals grown under different pressure and temperature conditions have different morphologies. Therefore, stable pressure and stable temperature are important factors for crystal shape.

This article will describe the common sense of diamond powder from six angles.

1. The impact strength of diamond powder

Impact strength is a scientific and comprehensive quality index, and static pressure strength is the most commonly used method in China to measure the quality of diamonds.

2. Magnetic susceptibility of diamond powder

Due to the use of metal as a catalyst in the synthesis of diamond, different diamond impurities are contained inside, especially the inclusions inside the crystal, which make diamond magnetic. It is convenient and nondestructive to measure the magnetic susceptibility to characterize the properties of diamond such as impurities, toughness, strength, specific gravity, thermal stability, etc., which has important practical value. The less impurity content, the smaller the magnetic susceptibility, the smaller the specific gravity, the lighter the color, the better the transparency, the higher the impact toughness, and the smaller the brittleness

3. Color

The color of diamond crystals is affected by temperature and the chemical environment in which they are located. The diamond crystals grown at low temperatures are darker in color and lighter in color at high temperatures. Various trace elements (impurities) as the crystal grows to determine the color of the diamond. For example, a small amount of boron will make the diamond crystal appear sky blue, and a large amount of boron will make it black (commonly known as black diamond). Nitrogen enters the diamond crystal to produce a yellow diamond, and most artificial diamonds are this kind of diamond. Aluminum prevents nitrogen from entering the growing diamond crystal. Make diamond crystals colorless. (natural diamond color).

4. Granularity

The concentration, uniformity, and tolerance range of diamond particle size are also important indicators for judging the quality of diamond. The particle size can be seen through a microscope, and it cannot be too large or too small. The particle size concentration should be high, and the tolerance range has a great influence on the electroplating diamond tools. In the electroplating tools, if the tolerance requirements are involved, the relevant tolerance requirements cannot be less than the range in this table, otherwise, the error of the diamond itself will already lead to tool failure. The overall requirements are not up to standard.

5. Transparency

When diamond is synthesized at high temperature and high pressure, the crystal nucleus first grows at the junction of graphite and a metal catalyst. If the crystal growth is too fast, the metal will be wrapped in the diamond crystal, forming small black spots of impurities. Because the thermal stability of impurities is not good, they will first expand and crack the diamond from the inside when exposed to heat, thus affecting the strength of the diamond.

6. Crystal form

The growth rate and shape of diamond crystals are more sensitive to pressure. Higher pressure causes more nucleation, faster growth rate, and easy formation of octahedral crystals. Diamond crystals grown under different pressure and temperature conditions have different morphologies. Therefore, stable pressure and stable temperature are important factors for crystal shape.

|

|

|

|

Related News

- Characteristics and Application of Resin Diamond Grinding Disc

- Glass Diamond Drill Bits Revolutionize Precision Drilling in the Glass Industry

- Innovative Diamond Resin Discs Revolutionize Hair Clipper Grinding Efficiency

- Diamond Micropowder Unleashes New Possibilities

- Diamond Powder Revolutionizes Drawing Die Polishing: Unveiling the Ultimate Finishing Solution

- Revolutionizing Gem Polishing with Diamond Micropowder

- Metal Diamond Wheels from HNHONGXIANG

- Diamond Micropowder on the Surface Grinder

- Diamond Micropowder Used in Polishing Liquid

- Glass Diamond Bits

- Classification of Grinder

- Surface Grinding and Surface Grinder